Introduction:

This product can be washed more than 200 times in industry;Can withstand 60 Bar atmospheric pressure and has stable and reliable performance under industrial and medical washing condition.

Specification:

|

Performance Specifications |

|

|

Model |

TS-9415 |

|

Protocol |

ISO 18000-6C(EPC gen2) |

|

Frequency Range |

902MHz-928MHz or 865MHz-868MHZ |

|

Chip type |

NXP Ucode 7M Chip |

|

Data Memory |

EPC 96bits, User 32bits |

|

Working mode |

Read and Write |

|

Reading distance |

Fixed reader:5m Handheld reader:2m |

|

Data Memory time |

50 years |

|

Write times |

100000 times |

|

Polarization |

Linear Polarization |

|

Physical Specification |

|

|

Dimension |

70mm *15mm* 1.5mm |

|

Installing mode |

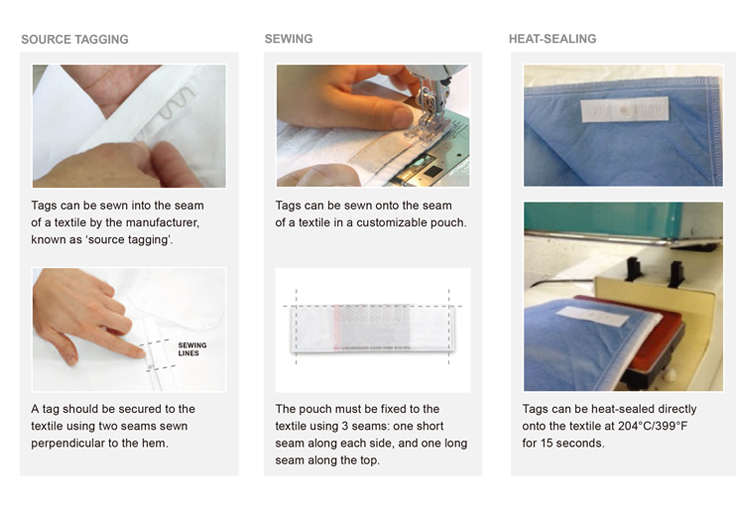

There are two installing mode: 1:Sewed in the curl or installed in the woven sleeve 2:215°C for 15 seconds and 4 bars (0.4MPa) pressure blanching method, or suture installation (please contact the original factory before installation for Solve the detailed installation method), or install it in the woven sleeve* |

|

Short-term temperature resistance |

1) Washing: 90 degrees, 15 minutes, 200 times 2) Converter pre-drying: 180 degrees, 30 minutes, 200 times 3) Ironing: 180 degrees, 10 seconds, 200 times 4) High temperature sterilization: 135 degrees, 20 minutes |

|

Base material |

Textile |

|

Under pressure |

60 bars |

|

Chemical properties |

Can withstand all chemicals in normal industrial washing processes |

|

Save humidity |

5 ~95 |

|

Working Temp |

-25℃~+110℃ |

|

Storage Temp |

-40℃~+85℃ |

|

Weight |

0.9g |

|

Surface Color |

White |

Main advantages:

♦ Really achieve and exceed 200 industrial washing life;

♦ 100% passed the memory write test;

♦ Material and design are tested for reliability;

♦ Products via European Finnish Tagformace equipment

♦ 100 RF consistency check

Main feature:

♦ Soft laundry tag can customize according to customer requirements;

♦ Soft laundry tag that meet MRI test requirements can be customized

♦ Soft, does not hurt textiles, feels good

♦ The chip module size is one of the smallest sizes on the international market;

♦ Can withstand 60Bars pressure, is a few of the few in the global market,200times pre-drying process and 180 degrees for 30 minutes;

Applications:

♦ Industrial washing management

♦ linen lease management;

♦ Standard garment management and washing management

♦ standard garment management and washing management

♦ Hospital linen and washing management;

♦ Military clothing and clothing management;

♦ Railway linen management and washing management;

♦ Police clothing management;

♦ Personnel management; access control management;

♦ Fire clothing and soft materials management; other applications requiring soft and pressure resistant products;

Notes:

*The suture cannot damage the metal wire and chip module on the label during sewing installation;

* When blanching is installed, when the temperature reaches 215 degrees to 218 degrees (15 seconds to 20 seconds), the blanching effect is excellent, and when it is lower than 210 degrees, there is a hidden danger of poor blanching effect;

* Different read and write facilities have different read and write performance.

Contact: Linda Chen

Phone: 18688748819

Tel: 0755-27575241

Email: sales@taseirfid.com

Add: C303,HuaChuangDa Cultural&Science Industry Park,HaiHui Road,Bao'An District 49,ShenZhen,China